Recognizing trends of the Spring Manufacturing Industry

If you are in the spring manufacturing industry, you know the wide variety of other industries that your products are a vital part of. Because of their many applications, springs must meet strict requirements. To stay competitive, spring producers must ensure consistent spring quality and effectively control spring fatigue while minimizing cost and scrap. The stakes are really high when it comes to delivering impeccable products that meet the growing customer demands.

Gain A Competitive Advantage

.jpg)

Long service life

Long service life

Reducing downtime and increasing productivity.

High performance

High performance

Enhance your grinding efficiency with superior cutting capabilities..jpg)

Stability

Stability

Maintain consistent and reliable grinding performance, even under demanding conditions..jpg)

Cool grinding

Cool grinding

Minimize thermal damage and optimize grinding performance with advanced cooling technology..jpg)

Self-sharpening

Self-sharpening

Maintain peak performance throughout the tool's lifespan with self-sharpening capabilities..jpg)

Minimal dressing adjustments

Minimal dressing adjustments

Reduce downtime and maintenance costs with infrequent dressing requirements.Ice Spring

The Innovative Solution For All Spring Types

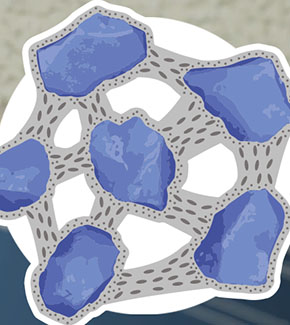

ICE SPRING is our innovative high-performance solution for spring end grinding. The unique combination of the grinding bond with the abrasive grains and defined structure enables a significant reduction of your grinding costs.

ICE SPRING can be used for various machine types and is available in all standard dimensions ranging from 175 to 1000 mm. The grinding wheel is designed to offer higher durability and stability of the grinding process.

Active Wheel

Activate Your Full Grinding Potential

ACTIVE WHEEL is our latest solution designed to unlock your full grinding potential. This new generation of Weiler wheel reduces the influence of different peripheral speeds within the grinding process. The unique dual composition of the product enables longer wheel life while increasing your productivity. The intricate design of the wheel prevents it from overheating in the middle sector.

ACTIVE WHEEL can be used on various machine types and is available in various diameters ranging from 175 to 1000 mm. The special composition of the product offers even surface grinding in one spring crossing.

Extra

Grind That Extra Mile

EXTRA is our solution developed specifically for treating spring ends of larger wire diameters. The winning combination of the correctly selected grain size with its new special resin-based bonding system yields optimal grinding results. The carefully developed specification enables you to use the same wheel for grinding spring ends of all materials. Because of its unique perforation, this grinding wheel will solve your challenges of spring overheating and burning.

EXTRA can be used on various machine types and is best suited for wire diameters varying from Ø10mm to Ø30mm. The special bonding system supports the cool grinding and enables a longer wheel life. To help you get the best results, Weiler delivers grinding wheels with different perforations according to your needs.

Optimizing Spring End Grinding: Enhancing Quality & Efficiency In 5 Steps

Although industrial compression springs might seem basic, they are essential components. One of the most important parts of spring production is smoothing spring ends. Compression springs need to be smooth for them to carry loads evenly. One way this can be achieved is by grinding their ends.