Success Story:

The Challenge

G-ratio

G-ratio

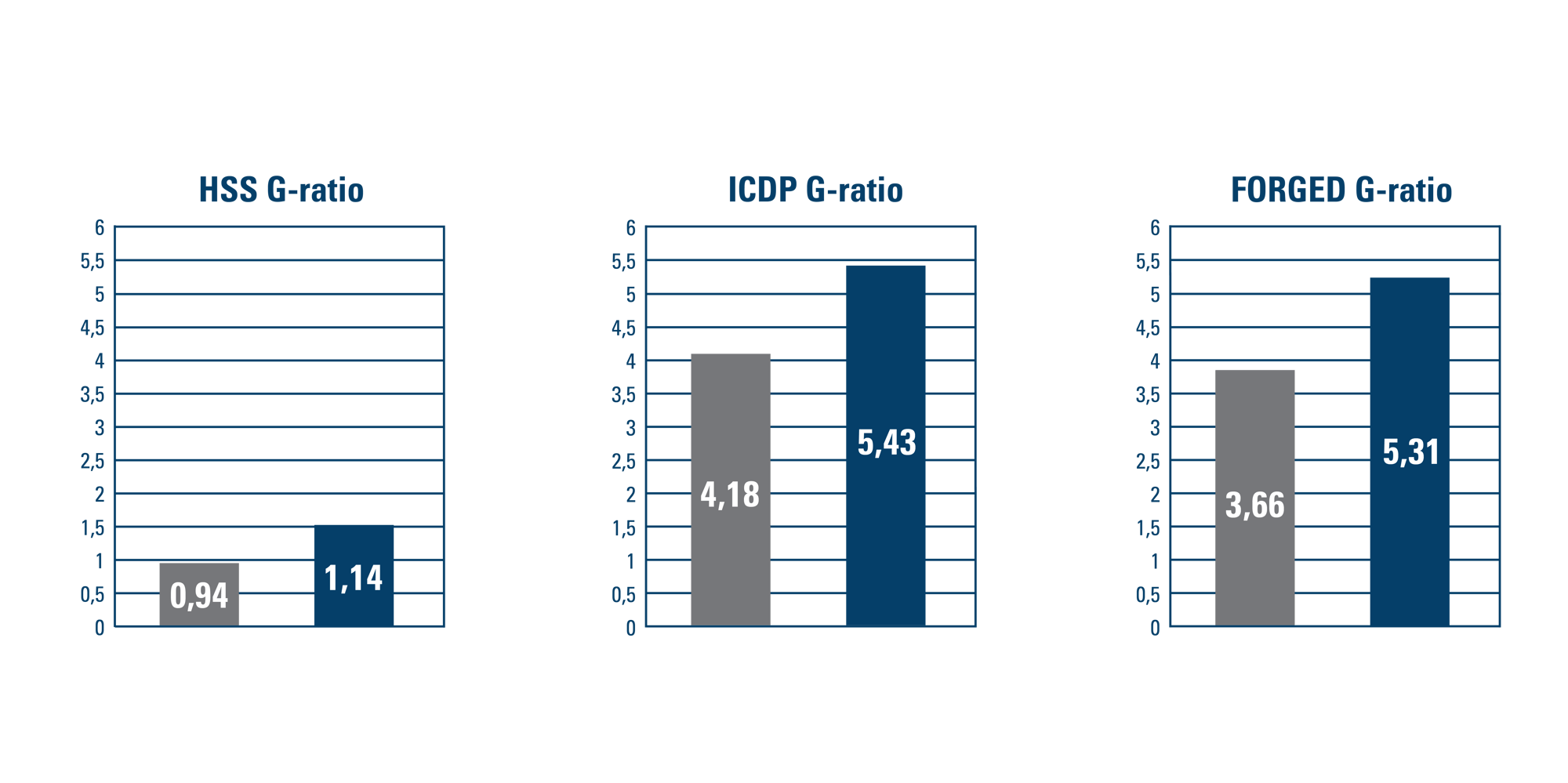

Significantly higher G-ratio to improve productivity

Surface Finish

Surface Finish

Superior surface finish quality, particularly on rougher forged rolls

Material Variety

Material Variety

Versatility across multiple materials (HSS, ICDP, and Forged)

Quality

Quality

Elimination of quality issues, including chatter marks and burning

G-ratio

G-ratio

Significantly higher G-ratio to improve productivity

Surface Finish

Surface Finish

Superior surface finish quality, particularly on rougher forged rolls

Material Variety

Material Variety

Versatility across multiple materials (HSS, ICDP, and Forged)

Quality

Quality

Elimination of quality issues, including chatter marks and burningTheir existing grinding wheels delivered suboptimal performance. They needed a solution.

The Data-Driven Solution

After comprehensively analyzing the specific requirements, we developed our innovative Fortis Mill grinding wheel technology. On-site testing produced remarkable results:

A Global Abrasives Partner Focused on Mutual Success

At Weiler Abrasives, our experience dates back to 1898 when Joseph E. Weiler began manufacturing brushes for the jewelry industry in Pforzheim, Germany. Since then, we’ve grown and evolved into a global manufacturer serving customers in over 80 countries with nearly 1,500 employees around the world.

“While the company has grown and expanded significantly since those humble beginnings, our commitment to developing long-term partnerships with customers, co-workers, and community hasn’t changed. We like to call that our 3C’s.” Chris Weiler, Executive Chairman.

Whether you are looking to improve your surface conditioning processes, optimize your consumable spend, or train your team on the safe and proper use of abrasives and brushes, Weiler has the people and expertise to help you achieve your goals.

Weiler: Your Competitive Edge

Product Innovations

Optimum Use Line

Patent pending Optimum Use Line provides a visual reference to help get the most out of the wheel. Using the wheel to its full life reduces change-overs, which helps users be more productive while reducing waste and abrasive spend.

Cut Back

PTiger Type 27 grinding wheels are designed with fiberglass cut back from the edge for aggressive grinding right out of the box.

Longer Life

Patent pending Optimum Use Line provides a visual reference to help get the most out of the wheel. Using the wheel to its full life reduces change-overs, which helps users be more productive while reducing waste and abrasive spend.

Optimum Use Line

Patent pending Optimum Use Line provides a visual reference to help get the most out of the wheel. Using the wheel to its full life reduces change-overs, which helps users be more productive while reducing waste and abrasive spend.

Our new metal grinding and cut off wheels are designed to be more than just a better product. They were created to help you do your best work.

Our new foundry line delivers a superior combination of life and cut-rate for maximum productivity.

These flap discs offer a paired flap design that delivers high performance grinding on aluminum.

Targets Achieved

- Superior G-ratio performance across all material types

- Improved surface finish quality in fewer passes

- Multi-material versatility with one solution

- Elimination of quality issues such as chatter marks and burning

Unleash Your Potential

The Weiler Advantage

Precise Surface Finish

Ability to achieve specific roughness requirements, whether a smoother or rougher finish is needed

Multi-Material Performance

Allowing one wheel to effectively grind HSS, ICDP, and forged steel

Productivity Improvements

Dramatic productivity improvements with G-ratios up to 3X higher than competitive options

Reduced Downtime

Reduced downtime from fewer wheel changes when processing different materials

Rapid Implementation and Adoption

Just 30 days after implementation, the end-user confirmed successful operation with positive operator feedback and adopted our solution, placing additional orders for the new grinding technology.