Best Practices for Gear Tooth Profile Grinding

By Konrad Coppens, Business Development, Weiler Abrasives

Gear tooth profile grinding is a precision finishing process essential to advanced gear manufacturing for many types and sizes of gears. It is used particularly in high-demand industries such as automotive, aerospace, energy, and heavy machinery.

Compared to gear cutting, profile grinding offers more accurate tooth finishes and greater versatility. It gives users that ability to make a specific profile and make profile corrections by dressing the wheel with the required corrections or modifications.

However, profile grinding can be a time-consuming and costly step in the gear manufacturing process, due in part to the stringent quality requirements. As a result, it’s important to select the right grinding wheel for gear tooth profile grinding and to use best practices that will help optimize quality and efficiency in these applications.

Best applications for profile grinding

Gear manufacturers can use profile grinding to grind both internal and external gears. The process offers great versatility for small gears as well as larger-diameter gears, such as those exceeding 9 meters, and to finish larger gear teeth greater than module 5. It’s also a good choice for gears that have clearance issues and do not allow for other processes like continuous generating gear grinding.

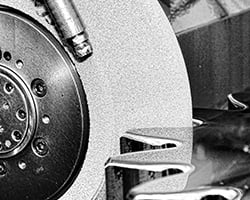

Profile grinding is a discontinuous process, meaning the right and left gear tooth flanks are ground at the same time, gap by gap. The grinding wheel is dressed in with the exact dimensions of the gear being ground. This helps make the process extremely accurate, since the profile is generated by the profile form that is dressed in the grinding wheel. Many machines use a rotary diamond dresser mounted in, either behind the grinding wheel, on top of the wheel, or below it. During the process, the dresser and grinding wheel (or both) move in multiple axis to achieve the desired gear tooth profile.

The grinding wheel runs between two opposing gear teeth, grinding both surfaces at the same time with exceptional accuracy. Vitrified bonded grinding wheels are used to modify or correct the profile of gear teeth, typically after heat treatment. The machine and gear geometry will determine the size of the wheel. When considering the dimensions of the gears, key factors that play a role in this include the module, pitch, pitch diameter, tip diameter, root diameter, number of teeth, tooth height, tip clearance, pressure angle, and helix angle. Also be sure to watch the profile line and flank line. The profile is the distance between the tooth's top and root, while the flank is the side of the gear. Gear grinding is usually the last step in the manufacturing process, after which the gear is prepared for assembly.

Profile grinding challenges

In most European manufacturing operations, maintaining competitiveness hinges on the ability to reduce cycle times and minimize thermal damage. Because the profile grinding process has such a high level of precision, there are numerous challenges to be aware of. These include:

- Grinding burns: Burning is usually the most crucial quality element in profile grinding. It can cause scrap and increased cycle times.

- Form holding: Also critical to quality is the grinding wheel’s ability to hold form, which directly impacts cycle time and gear geometry.

- Grinding wheel life: Some wheels deliver longer tool life while helping users meet necessary quality requirements. Proper grinding techniques and strategies can also help extend wheel life. This makes application training for profile grinding operators especially important.

- Incorrect parameters: Using incorrect programming parameters can result in increased cycle time, poor gear quality, burning and increased scrap. Consulting with an application engineer from an abrasives manufacturer can help ensure optimal results.

- Production bottlenecks: Profile grinding can be a source of bottlenecks. Very large gears may have a cycle time of anywhere from two to 12 hours, for example. A change to the grinding wheel itself or a parameter adjustment can potentially result in significant time savings.

Selecting advanced wheel materials and using best practices in wheel dressing and machine control can help manufacturers address these challenges and deliver high-quality gears.

Abrasive products for profile grinding

Many formulations are available in wheels for profile grinding. Choosing the right wheel involves considering many factors, including gear hardness and size, wheel size, and rated speed. Users will get different cutting properties, durability, and product life with different wheels.

An open porosity, vitrified bond wheel that uses either aluminum oxide grains or high-performance ceramic grains is a common choice for profile grinding. Using a wheel with induced porosity — or very large pores — helps reduce the risk of damaging or scrapping the part. This helps optimize results and reduce scrap costs.

Working with an abrasives manufacturer to assess application requirements and produce a wheel for the specific profile grinding application is a good way to deliver optimized performance. A quality manufacturer can engineer customized grinding wheels in a variety of grit sizes and abrasive grain types that are adapted for use with a wide range of CNC machines.

Tips to improve results in profile grinding

Grinding strategy plays a key role in gear quality. There are also several tips to keep in mind to help reduce cycle time and optimize results in profile grinding.

- Improve form holding:

Grind time and dress time are the two key elements in the grinding cycle to consider. The in-cycle dress time can be between three to eight minutes or more. Better form holding means longer cutting between dress cycles, resulting in faster cycle times. This makes application training for profile grinding operators especially important to ensure they are using proper grinding strategies. Work with an abrasives manufacturer to formulate a wheel with optimal grain and bond technology to maximize form holding.

- Reduce heat in cutting:

When the tooth surface is exposed to very high temperatures in the grinding process, it results in burning, or tempering. This can decrease hardness and cause stress to the gear material, causing possible cracking that can lead to gear failure. A high-volume coolant system in the machine provides adequate flooding properties to wash away metal chips created by the grinding wheel. Choosing a grinding wheel that cuts cooler can provide several benefits. A wheel grinds cooler by maximizing the timing of the grain releasing from the bond and by having the proper grain technology for the job. In addition, having the gear blank roughing process as accurate as possible before grind will lower the risk for quality failures and help stabilize the grinding operation.

- Increase wheel life with higher cutting volumes (V’w):

Cutting volume is the measure of how much gear tooth material can be removed before the geometry must be corrected, also known as when form loss occurs. During machine setup, the form is dressed into the wheel and the gear is ground. The same form on the wheel is copied onto the gear. How many times this can be done before the form is out of tolerance is known as the achievable cutting volume, which is a volumetric calculation. Optimal grinding and dressing strategies can help users reduce cycle times. Grinding wheels have different cutting volumes. Generally, economical wheels have a lower cutting volume, while high-performance wheels have a much higher cutting volume, which can prolong wheel life and reduce cycle times. A lower cycle time is achieved by reducing the amount of dress intervals. When the grinding strategy is correct and optimized, you will get the best result from a high-performance wheel.

- Reduce cycle time with high material removal rates (Q’w):

Improving the material removal rate (MRR) will also decrease cycle time. Material removal rate is a metric used to understand how fast workpiece material is removed by the grinding wheel. The higher the value, the higher the rate of removal. A higher MRR can be achieved by either increasing the amount of stock or increasing the wheel feed rate. The formula for Q’w is:

Q’w = (ae * vw)/60

where,

ae = amount of material, units in volume

vw = feed rate, units in distance/time

A high feed rate may be preferred instead of a low feed rate and high stock removal amount. This is a common factor used in grinding and is usually one of the first questions asked by operators. The Q’w formula shows you can adjust the material removal rate by understanding how to apply the correct grinding wheel technology to optimize stock amount, feed rate or both. It is important to note that gears with a low number of teeth have a variable Q’w along the profile from root to tip. Because the profile angle varies from root to tip on medium- to large-pitch gears, this type of gear will require a different grind strategy to achieve quality and prevent burn. Q’w is impacted by the coolant system, gear geometry and other factors — similar to other elements of the grind process.

Optimizing results

Gear manufacturers want to be cost-effective and reduce cycle time in profile grinding, but first and foremost they must maintain extremely high quality, making cycle prediction with programming crucial. The right grinding wheel manufacturer understands these challenges and can work with users and engineers to formulate a wheel that is the best fit for each specific application — to help save costs and optimize cycle time without sacrificing quality.