Strip discs deliver superior cleaning power and extended product life for steel and stainless steel

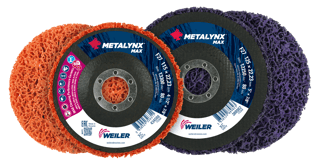

MARIBOR, Slovenia — Jan. 28, 2025 — Weiler Abrasives, a leading provider of abrasives and power brushes for surface conditioning, is excited to announce a new ceramic option in its non-woven surface conditioning disc lineup designed to remove coatings and rust in preparation for welding and manufacturing operations. New Metalynx Ceramic non-woven strip discs deliver superior cleaning power and extended product life for applications in metal fabrication, shipbuilding, automotive and other industries.

“Our new Metalynx Ceramic strip discs use an innovative formulation that provides industry-leading material removal and cleaning power for maximum surface cleaning efficiency,” said Michael Zulauf, product design engineer, Weiler Abrasives. “With an optimal balance between conformability and toughness, these discs help users clean faster and clean more.”

Metalynx Ceramic strip discs clean up to 20% more material and are up to 20% faster than a leading competitive product, delivering superior cleaning power and extended product life for steel and stainless steel. The self-sharpening ceramic grains effortlessly clean welds and remove thick coatings and stubborn rust, maintaining a consistent cut rate for greater efficiency. The ultra-flexible non-woven nylon fiber and resin formula create a wider footprint and increases the contact area with the work surface, boosting productivity without compromising wheel life. This results in industry-leading material removal and cleaning power for maximum surface cleaning efficiency. These discs are ideal for weld cleaning, surface preparation and blending, as well as removing thick coatings and heavy rust.

In addition, Weiler Abrasive has upgraded its Metalynx SiC strip discs for improved performance and life. These silicon carbide discs clean up to 30% more material than the industry leader in this category, offering a fast-cleaning, long-life solution for steel and stainless steel. Silicon carbide grains provide a high initial cut and penetration, making them ideal for cleaning hard surfaces such as hard-grade steel, structural steel, hot-rolled steel and stainless steel. The ultra-flexible non-woven nylon fiber and resin formula creates a wider footprint and increases the contact area with the work surface, boosting productivity without compromising wheel life. The discs are low sparking, which is necessary for confined spaces and areas where hot work is not permitted. Metalynx SiC strip discs provide best-in-class material removal, ensuring a durable and long-lasting solution for user’s surface cleaning needs. These discs are ideal for removing paint, rust, light mill scale and varnish as well as for weld cleaning.

The Metalynx Ceramic and Metalynx SiC strip discs use a contaminant-free formula that provides a worry-free solution for stainless steel.

Weiler Abrasives also delivers expertise and support through safety training and consumable productivity assessments, helping ensure that operations are using the correct products for their applications.

Learn more about how Metalynx Ceramic and Metalynx SiC strip discs can deliver efficiency and cost savings for operations at emea.weilerabrasives.com/catalog/products/non-woven-abrasives/surface-conditioning-discs.

# # #

About Weiler Abrasives Group

As an industry leader and global manufacturer of surface conditioning solutions, Weiler Abrasives Group is dedicated to forging collaborative relationships with our customers in diverse markets — Metal Fabrication; Industrial Production; Maintenance, Repair & Operations — to tackle their toughest cleaning, grinding, cutting, deburring and finishing challenges.

Weiler Abrasives, Maribor, Slovenia • +386 2 3331 600 • emea.weilerabrasives.com