Fortis Mill Roll Grinding Solutions

Recognizing the Evolving Demands of Roll Grinding Operations

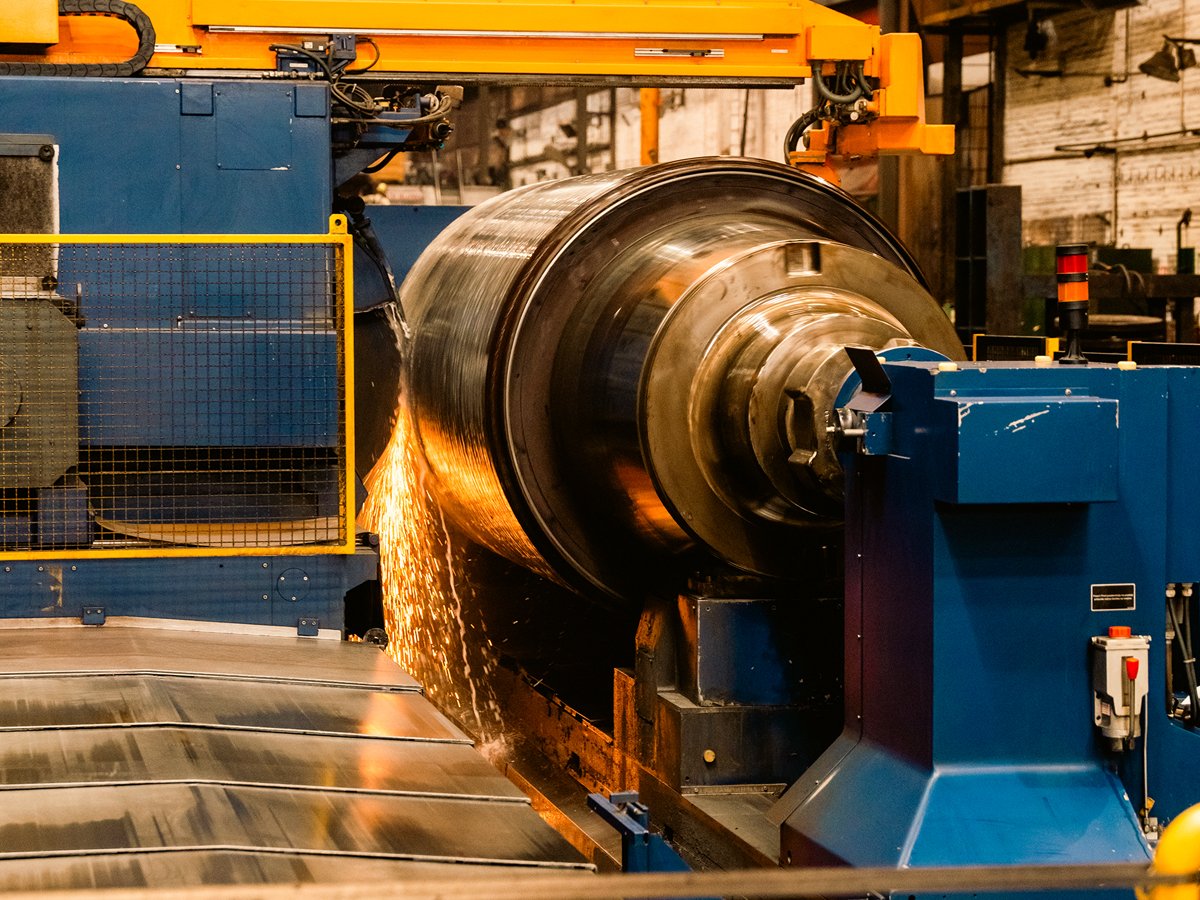

Roll grinding is a specialized form of external cylindrical grinding designed for rolls that operate under extreme pressure, heat, and mechanical load. Used in both hot and cold rolling mills, these rolls require regular maintenance to maintain surface quality, consistency, and mill uptime.

Today’s steel producers face rising energy costs, tighter tolerances, and increased expectations for productivity. Rolls made from hard-to-grind materials demand engineered abrasive solutions with advanced grain technology and bonding systems to achieve high G-ratios and material removal rates (MRR)—without compromising roll integrity or safety.

Helping You Perform When It Matters Most

We help steel producers and roll shops meet today’s challenges with Fortis Mill roll grinding solutions, engineered to optimize grinding performance across hot and cold mill applications.

Fortis Mill wheels maximize G-ratio and MRR while delivering consistent surface finishes and reduced cycle times. The result is fewer wheel changeovers, lower consumable spend, and reliable performance—pass after pass.

Tailored Solutions

Tailored Solutions

Custom formulations for various roll materials enhance performance and reduce abrasive costs.

Reduce Vibration

Reduce Vibration

Eliminate surface imperfections, improve roll quality, and extend the life of rolls and equipment.

Shorten Cycle Times

Shorten Cycle Times

Enhancing abrasive performance reduces cycle times and minimizes production downtime.

Increase Precision

Increase Precision

Achieve tighter tolerances by eliminating variations and increasing product quality.

Tailored Solutions

Tailored Solutions

Custom formulations for various roll materials enhance performance and reduce abrasive costs.

Reduce Vibration

Reduce Vibration

Eliminate surface imperfections, improve roll quality, and extend the life of rolls and equipment.

Shorten Cycle Times

Shorten Cycle Times

Enhancing abrasive performance reduces cycle times and minimizes production downtime.

Increase Precision

Increase Precision

Achieve tighter tolerances by eliminating variations and increasing product quality.Weiler Process Solutions: Bringing Process, Expertise, And Partnership Together.

Weiler Process Solutions (WPS) complements the Fortis Mill product line by combining advanced abrasive technology with on-site technical expertise.

Through WPS, our engineers work alongside your team to optimize grinding processes, reduce total cost per roll, improve productivity, and ensure consistent, repeatable results—turning today’s challenges into a competitive advantage.

LEARN ABOUT WPSHot Roll Mill Grinding

Fortis Mill Hot Roll Grinding Solutions That Deliver Results

In hot rolling mills, rolls are exposed to extreme pressure and heat, leading to deformation and surface wear. Fortis Mill Hot Roll Grinding Wheels are engineered to deliver high material removal rates, shorter grinding cycles, and extended wheel life—helping maximize uptime and productivity.

Fortis Mill wheels feature advanced ceramic grain technology and comply with EN 12413 and oSa standards. Designed for forged and cast rolls, they provide higher G-ratios, reduced changeovers, and lower total grinding costs.

Learn More

Cold Roll Mill Grinding

Fortis Mill Cold Roll Grinding for Precision and Consistency

Fortis Mill Cold Roll Grinding Wheels are designed to achieve flawless surface finishes with precision and consistency. Advanced ceramic grain technology delivers smooth, scratch-free finishes while improving G-ratio and wheel life—even on hard-to-grind materials.

The result is reduced rework, lower operating costs, and consistent surface quality that meets demanding cold mill specifications.

Learn More

Product Innovations

Cold Roll Mill Defects Eliminated, Costs Cut by €20,000

Premium suppliers failed to solve surface defects. A process-driven grinding approach doubled wheel life, tripled G-ratio, and eliminated scratches.

Read the Case Study

One Wheel. Three Materials. Up to 3X Higher G-Ratio

Fortis Mill technology delivers superior surface finish and productivity across HSS, ICDP, and forged rolls—without chatter or burning.

Read the Case Study