The €20,000 Question Industry Giants Couldn't Answer

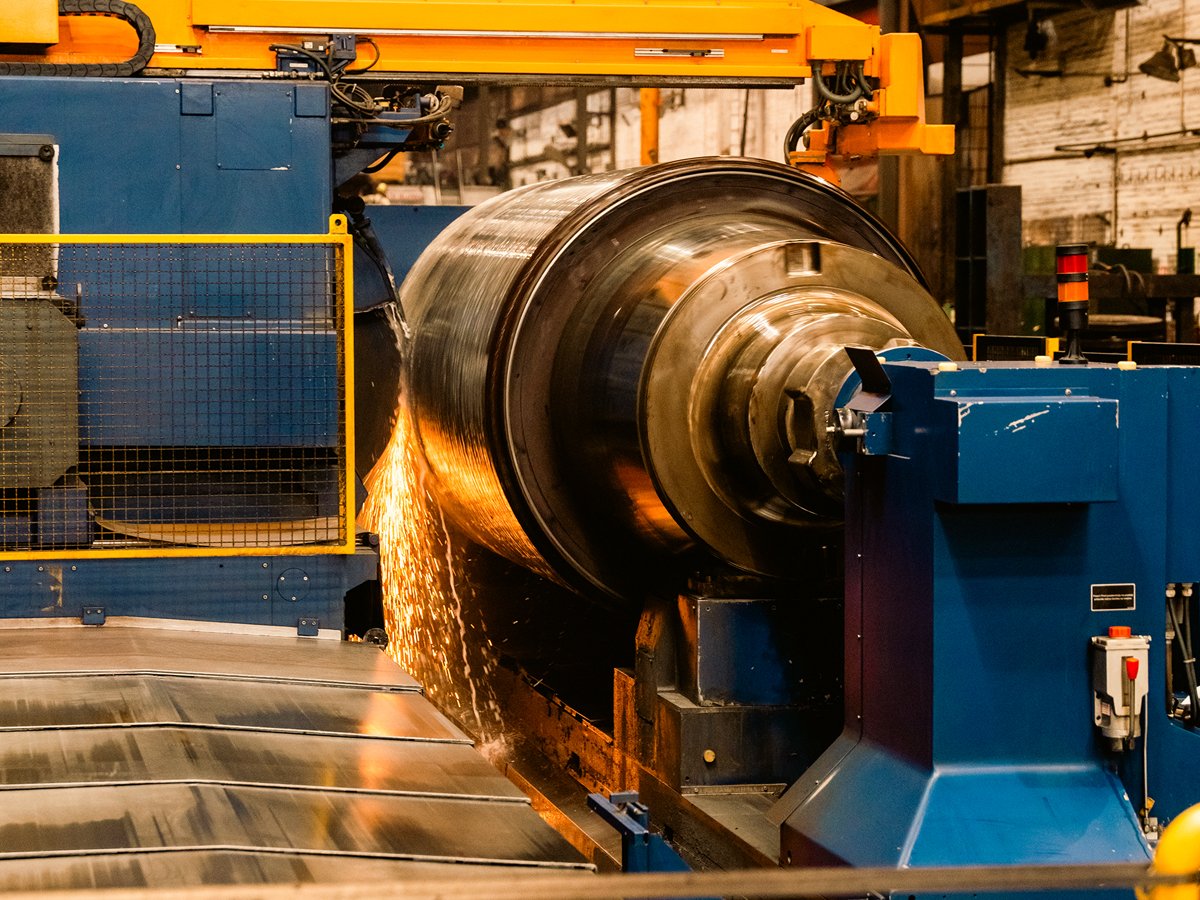

A major European steel producer was trapped in a frustrating cycle. Despite working with industry-leading suppliers, their cold roll mill grinding wheels kept leaving visible scratch patterns across expensive rolls. Quality was suffering, costs were climbing, and their established vendors had run out of answers. When our technical team arrived, they didn't show up to sell products. They showed up with the expertise to ask the right questions and a commitment to find real solutions. What happened next was groundbreaking!

The Challenge

Persistent Surface Defects

Persistent Surface Defects

Fine chatter marks and scratches plagued roll surfaces.

Premium Suppliers, Inferior Results

Premium Suppliers, Inferior Results

Established supplier couldn't eliminate defects or deliver consistent quality.

Equipment Constraints

Equipment Constraints

Solutions had to work within existing machinery.

Rising Costs, Falling Efficiency

Rising Costs, Falling Efficiency

Abrasive spend and quality issues compounded operational problems.

Persistent Surface Defects

Persistent Surface Defects

Fine chatter marks and scratches plagued roll surfaces.

Premium Suppliers, Inferior Results

Premium Suppliers, Inferior Results

Established supplier couldn't eliminate defects or deliver consistent quality.

Equipment Constraints

Equipment Constraints

Solutions had to work within existing machinery.

Rising Costs, Falling Efficiency

Rising Costs, Falling Efficiency

Abrasive spend and quality issues compounded operational problems.

Our Solution

We began with a complete process audit, examining conditions and grinding parameters. We saw that we could do a lot better. We proposed our Fortis Mill wheel, engineered specifically for cold roll mill applications. The team analyzed baseline data from the existing solution, then systematically optimized parameters for the Fortis Mill wheel's unique characteristics. Through methodical testing, we solved what industry leaders couldn't: delivering superior surface quality and doubled wheel life within their existing reality.

We didn’t bring a product catalog. We brought a different approach.

A Global Abrasives Partner Focused on Mutual Success

At Weiler Abrasives, our experience dates back to 1898 when Joseph E. Weiler began manufacturing brushes for the jewelry industry in Pforzheim, Germany. Since then, we’ve grown and evolved into a global manufacturer serving customers in over 80 countries with nearly 1,500 employees around the world.

“While the company has grown and expanded significantly since those humble beginnings, our commitment to developing long-term partnerships with customers, co-workers, and community hasn’t changed. We like to call that our 3C’s.” Chris Weiler, Executive Chairman.

Whether you are looking to improve your surface conditioning processes, optimize your consumable spend, or train your team on the safe and proper use of abrasives and brushes, Weiler has the people and expertise to help you achieve your goals.

Weiler: Your Competitive Edge

Product Innovations

Optimum Use Line

Patent pending Optimum Use Line provides a visual reference to help get the most out of the wheel. Using the wheel to its full life reduces change-overs, which helps users be more productive while reducing waste and abrasive spend.

Cut Back

PTiger Type 27 grinding wheels are designed with fiberglass cut back from the edge for aggressive grinding right out of the box.

Longer Life

Patent pending Optimum Use Line provides a visual reference to help get the most out of the wheel. Using the wheel to its full life reduces change-overs, which helps users be more productive while reducing waste and abrasive spend.

Optimum Use Line

Patent pending Optimum Use Line provides a visual reference to help get the most out of the wheel. Using the wheel to its full life reduces change-overs, which helps users be more productive while reducing waste and abrasive spend.

Our new metal grinding and cut off wheels are designed to be more than just a better product. They were created to help you do your best work.

Our new foundry line delivers a superior combination of life and cut-rate for maximum productivity.

These flap discs offer a paired flap design that delivers high performance grinding on aluminum.

The Impact

Surface Defects Eliminated

Chatter marks and scratches completely resolved.

Wheel Life Doubled

Fortis Mill wheels lasted twice as long as the previous premium solution.

G-Ratio Tripled

Three times higher, zero compromise on quality.

Annual Savings: €20,000

Wheel consumption cut in half, reducing costs by €15,000-20,000.

Your competitors are paying half as much for twice the performance.

Discover what your current supplier isn't telling you.