Vprašanje za 20.000 evrov, na katerega veliki igralci v industriji niso znali odgovoriti

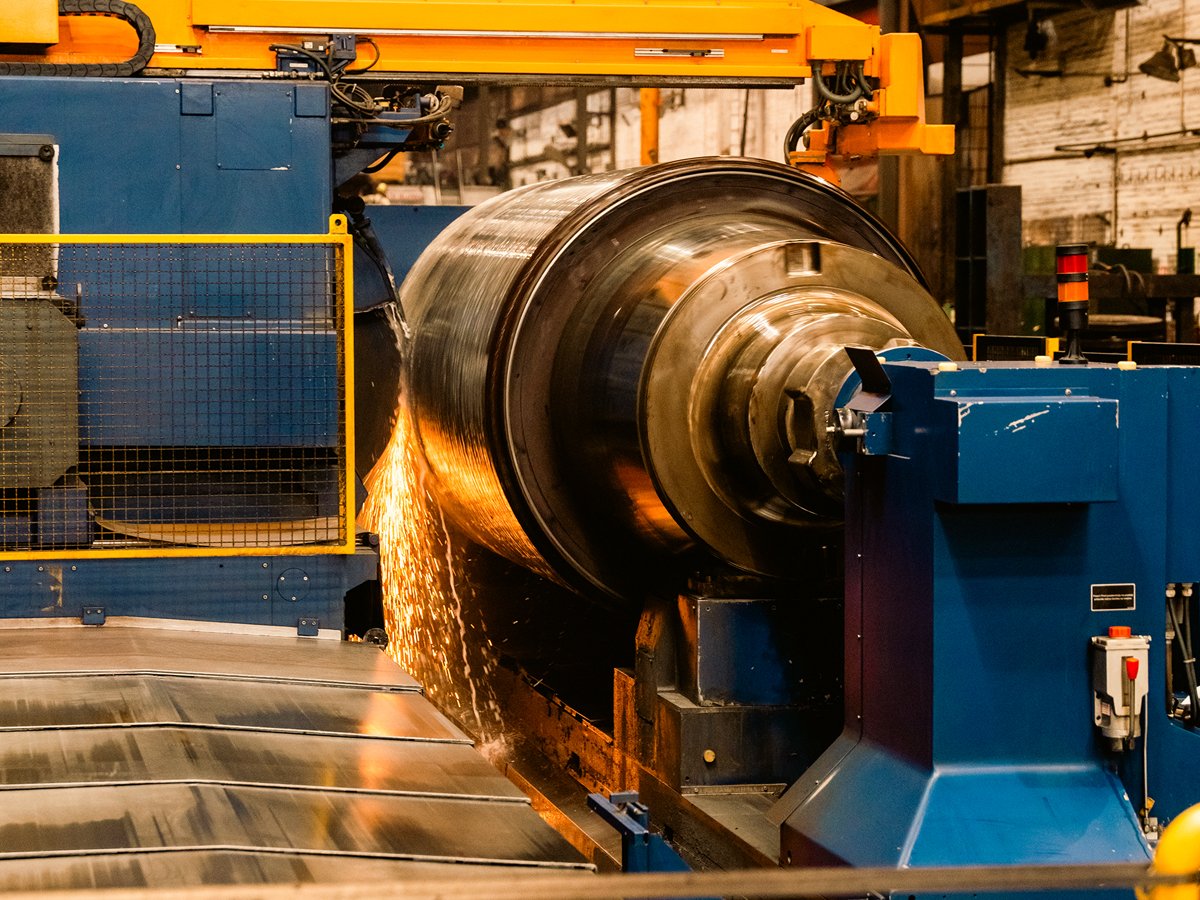

Velik evropski proizvajalec valjev je bil ujet v ponavljajoče se težave z doseganjem standardnih parametrov površine svojih izdelkov.Kljub sodelovanju z vodilnimi dobavitelji v industriji so njihovi brusi na dragih valjih puščali vidne praske. Kakovost je trpela, stroški so se višali, njihovi uveljavljeni dobavitelji pa niso imeli več odgovorov. Ko je prišel naš tehnični tim, ni prišel prodajat izdelkov. Prišel je s strokovnim znanjem, da je zastavil prava vprašanja, in z zavezo, da poišče prave rešitve. Kar se je zgodilo potem, je bilo revolucionarno!

Izziv

Vztrajne površinske napake

Vztrajne površinske napake

Na površini valjev so bile vidne drobne praske in odrgnine.

Vrhunski dobavitelji, slabši rezultati

Vrhunski dobavitelji, slabši rezultati

Uveljavljeni dobavitelj ni mogel odpraviti napak ali zagotoviti dosledne kakovosti.

Omejitve opreme

Omejitve opreme

Rešitve so morale delovati v okviru obstoječih strojev.

Naraščajoči stroški, padajoča učinkovitost

Naraščajoči stroški, padajoča učinkovitost

Abrazivni stroški in težave s kakovostjo so še poslabšali operativne težave.

Vztrajne površinske napake

Vztrajne površinske napake

Na površini valjev so bile vidne drobne praske in odrgnine.

Vrhunski dobavitelji, slabši rezultati

Vrhunski dobavitelji, slabši rezultati

Uveljavljeni dobavitelj ni mogel odpraviti napak ali zagotoviti dosledne kakovosti.

Omejitve opreme

Omejitve opreme

Rešitve so morale delovati v okviru obstoječih strojev.

Naraščajoči stroški, padajoča učinkovitost

Naraščajoči stroški, padajoča učinkovitost

Abrazivni stroški in težave s kakovostjo so še poslabšali operativne težave.

Naša rešitev

Začeli smo s celovitim pregledom procesa, pri čemer smo preučili pogoje in parametre brušenja. Ugotovili smo, da lahko dosežemo veliko boljše rezultate. Predlagali smo naš Fortis Mill, ki je bil posebej zasnovan za uporabo v hladnih valjarskih obratih. Ekipa je analizirala osnovne podatke iz obstoječe rešitve, nato pa sistematično optimizirala parametre za edinstvene lastnosti brusa Fortis Mill. S sistematičnim testiranjem smo rešili tisto, česar vodilni v industriji niso mogli: zagotovili smo vrhunsko kakovost površine in podvojili življenjsko dobo brusa v okviru obstoječih razmer.

Nismo prinesli kataloga izdelkov. Prinesli smo drugačen pristop.

A Global Abrasives Partner Focused on Mutual Success

At Weiler Abrasives, our experience dates back to 1898 when Joseph E. Weiler began manufacturing brushes for the jewelry industry in Pforzheim, Germany. Since then, we’ve grown and evolved into a global manufacturer serving customers in over 80 countries with nearly 1,500 employees around the world.

“While the company has grown and expanded significantly since those humble beginnings, our commitment to developing long-term partnerships with customers, co-workers, and community hasn’t changed. We like to call that our 3C’s.” Chris Weiler, Executive Chairman.

Whether you are looking to improve your surface conditioning processes, optimize your consumable spend, or train your team on the safe and proper use of abrasives and brushes, Weiler has the people and expertise to help you achieve your goals.

Weiler: Your Competitive Edge

Product Innovations

Optimum Use Line

Patent pending Optimum Use Line provides a visual reference to help get the most out of the wheel. Using the wheel to its full life reduces change-overs, which helps users be more productive while reducing waste and abrasive spend.

Cut Back

PTiger Type 27 grinding wheels are designed with fiberglass cut back from the edge for aggressive grinding right out of the box.

Longer Life

Patent pending Optimum Use Line provides a visual reference to help get the most out of the wheel. Using the wheel to its full life reduces change-overs, which helps users be more productive while reducing waste and abrasive spend.

Optimum Use Line

Patent pending Optimum Use Line provides a visual reference to help get the most out of the wheel. Using the wheel to its full life reduces change-overs, which helps users be more productive while reducing waste and abrasive spend.

Our new metal grinding and cut off wheels are designed to be more than just a better product. They were created to help you do your best work.

Our new foundry line delivers a superior combination of life and cut-rate for maximum productivity.

These flap discs offer a paired flap design that delivers high performance grinding on aluminum.

Vpliv

Odpravljene površinske napake

Značilnosti in praske so popolnoma odpravljene.

Podvojena življenjska doba brusa

Fortis Mill je zdržal dvakrat dlje kot prejšnja vrhunska rešitev.

G-razmerje se je potrojilo

Trikrat višja, brez kompromisov pri kakovosti.

Letni prihranki: 20.000 EUR

Poraba brusov se je zmanjšala za polovico, kar je znižalo stroške za 15.000–20.000 evrov.

Vaši konkurenti plačujejo polovico manj za dvakrat večjo zmogljivost.

Odkrijte, česa vam vaš trenutni dobavitelj ne pove.